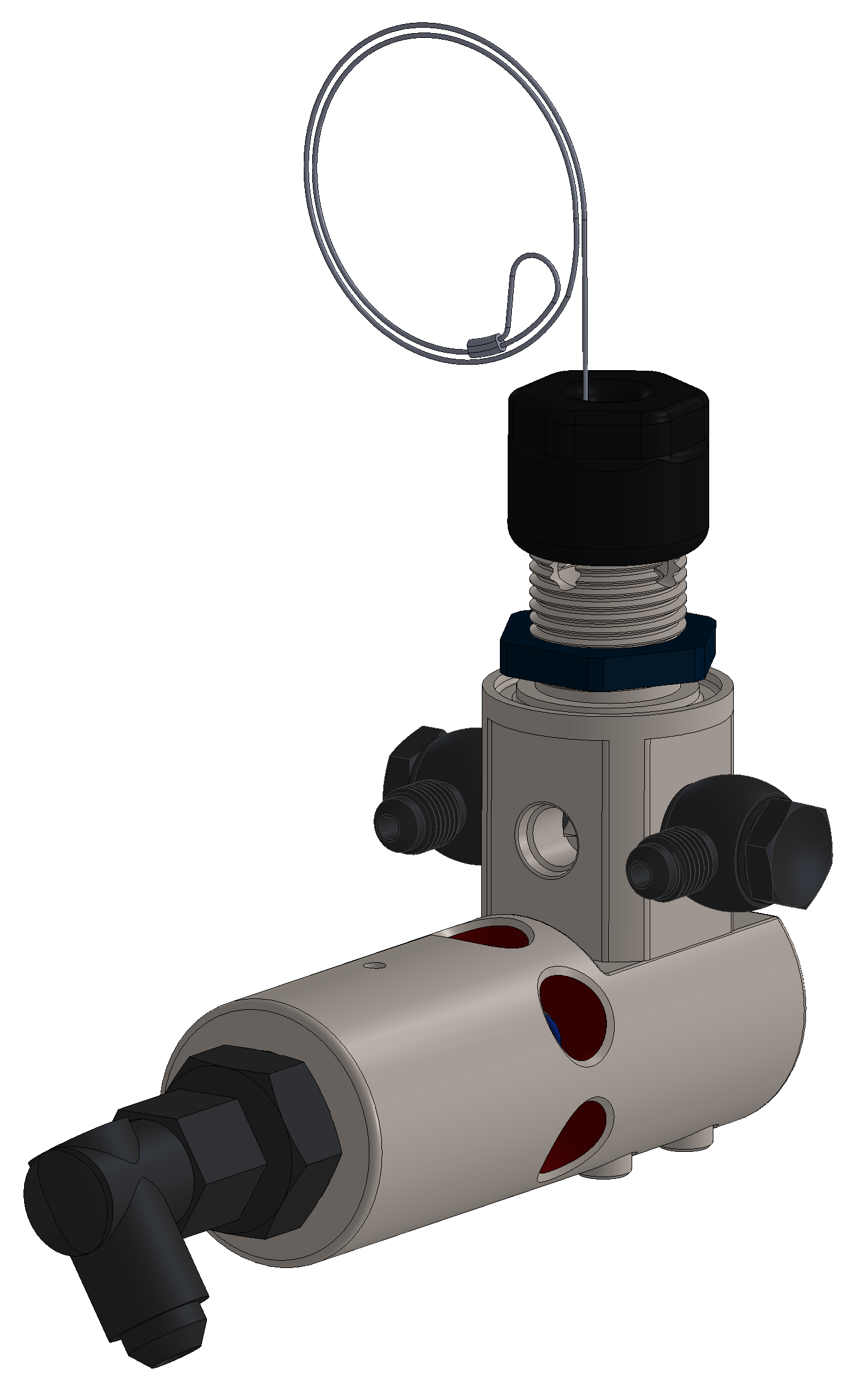

STT Inflation Valve Assembly

(STT-IVA)

The STT Inflation Valve Assembly is a complete exercise in answering the specific challenge in front of today’s warfighter, in its entirety. Academically, the valve need only be an actuated dump valve that empties the tanks into the bladder. That is what came before… and it is what they asked for initially.

We knew we could do better. Time and again the legacy inflation valve assembly, (originally designed for Naval Aviation as a life raft inflation valve) was the weakest link. The only thing it had going for it was a Naval Stock Number (NSN).

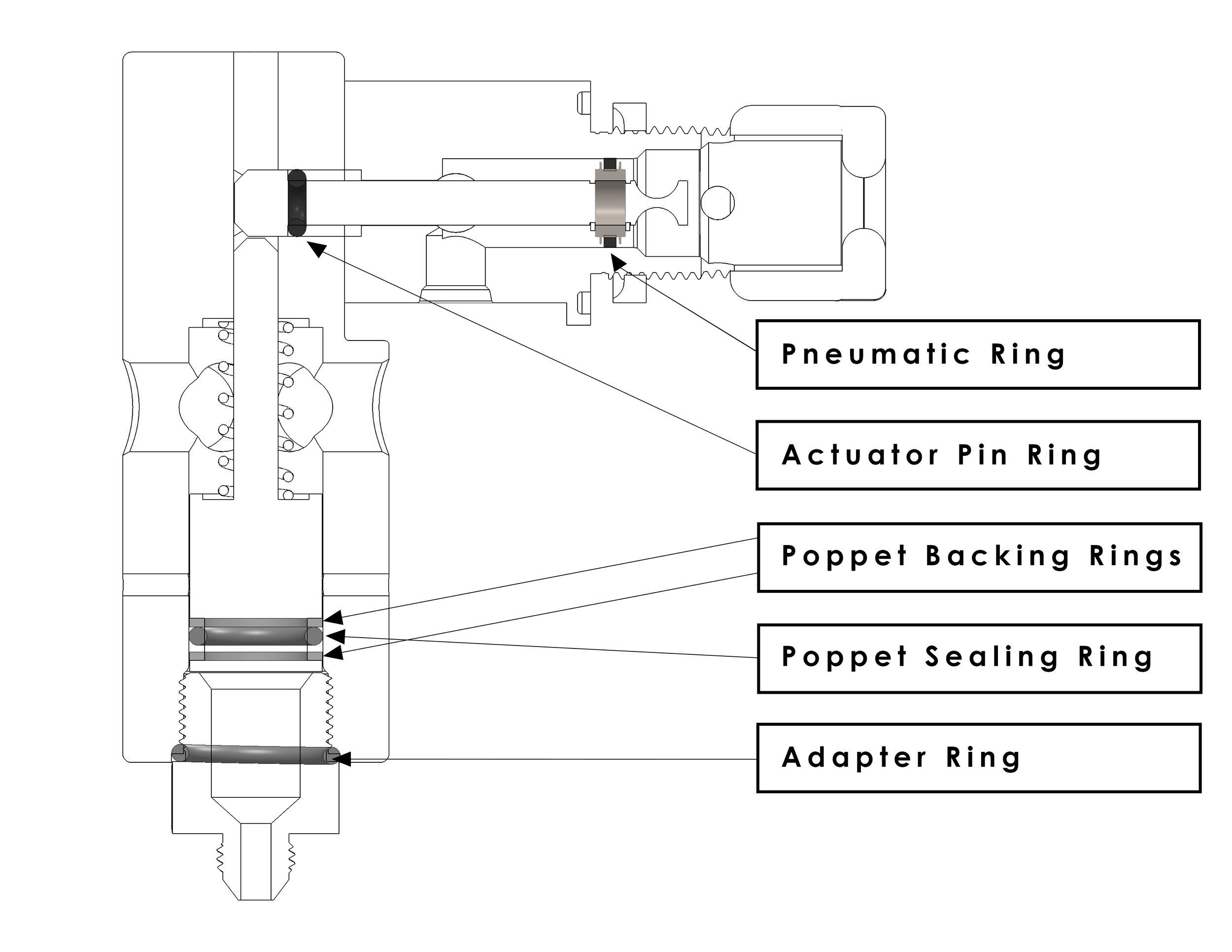

With the proverbial clean sheet of paper, we determined what the best possible valve would be for these systems. It needed to be corrosion resistant, so the entire assembly is milled from 316 Stainless Steel, known for its corrosion resistance properties. Being 100% 316 meant no bi-metallic, or galvanic corrosion between dissimilar metals… The poppet is designed for low pressure (130 psi) use, and as such generates 800x the actuation force compared to legacy. This means that it will power through any debris or issues in the firing chain.

Saving the best for last, it is also a pressure-retaining valve that automatically resets. This means that not only are only two reset steps… “Replace Lanyard, Replace safety pin” but once “completely” drained, it retains approximately 50 psi in the bottles. It isn’t very much volume lost to do this, but by leaving some pressure in the tanks, the tanks no longer require (mandated by US Navy and all US SCUBA regulatory bodies) a mandatory bottle disassembly and visual inspection to recharge the bottles. You see, an empty bottle means it was all the way open at some point, and was capable of ingesting contaminants, water, debris, corrosion etc… Pressure in a bottle is a sign that it hasn’t been all the way empty, so contaminants could not have entered the volume. Not only are visual inspections time consuming and expensive, but they can throw a terrible wrench in a plan that includes multiple dives in a given period. Our air retention is a big deal, and it is in direct response to the community essentially begging for a solution to the logistical challenge.

This is the final answer to the inflation valve challenge.

Click on the above links to find manuals, PMS cards and Quick Start guides for the system.

Full Resetting Procedure

With all moving parts made from 316 corrosion resistant Stainless Steel, the STT-Inflation Valve Assembly is designed to take a beating, and even survive the often less than perfect PMS procedures often inflicted upon military dive gear. The system is designed to retain 50# of pressure in it, preventing a mandatory visual inspection every time the bottle is drained to zero, a characteristic of all other inflation valves. Further, after the pressure is removed, it is designed to automatically reset the poppet, requiring only the manual pull lanyard and actuation pin to be reset. No more disassembly of the inflation valve assemblies.

Follow along with the video and see how the lanyard and pin is reset completely in a little under 40 seconds.